Minimizing risk to your workers is an important component of maintaining smooth operations, business reputation and company assets. We understand the unique hazards of working in confined spaces and at high angles. Our experienced safety managers can ensure that you reduce and avoid risks to your high angle or confined space workers.

RAC’s experts identify and assess threats with comprehensive logistical planning and ensure compliance with all local, provincial and federal regulations. We also offer specialized on-site training programs (Link to site specific training) for staff working on vertical surfaces, in confined spaces or in sub surface conditions. Identifying electrical, atmospheric and mechanical hazards is the first step toward ensuring worker safety. Evaluating the ventilation of an area and strategizing rescue entry and access points are also important components. We also ensure that your personnel have consistent lines of communication for properly monitoring and providing updates on their progress and safety. Fall hazards, hazardous atmospheres, chemical exposure and the possibility of entrapment are just a few of the dangers of working in confined spaces. RAC offers tried and true measures for preventing injuries and accidental death for workers in confined spaces. Our logistics specialists procure safety and abseiling equipment, analyze the risks of working in your particular confined spaces, and effectively organize and plan for an occurrence of a crisis situations. Comprehensive knowledge of safety equipment and practices allows are logistical specialists to design integrated safety systems for your jobsite. Using comprehensive training and certifications from the Society of Professional Rope Access Technicians (SPRAT) and the Industrial Rope Access Trade Association (IRATA) we provide sophisticated industry standard protocol for rope suspended confined space workers. Rope access is a minimal impact method for working in confined spaces that is accompanied by developed action plans for emergency response. Rope access can solve logistical problems by cutting out the costs of large scaffold teams and heavy machinery. Prevent facility shut downs through logistical planning and effective safety management. RAC preforms and plans for vertical rescues to ensure that your personnel avoid hazards when abseiling. Our safety technicians can make logistical arrangements, plan and implement safety logistics and review risk management for all of your worker‘s high angle activities. Risk assessments and risk analysis of industrial and construction activities allow us to comprehensively review all possible choices of access methods. Our risk assessments evaluate the presence of hazards, the feasibility of access and the possibility of using alternate working methods such as suspended platforms. They establish exclusion zones (areas that can’t be reached), obstruction hazards and the types of access necessary: descent, ascent, traverse, suspension or aided climbing.Confined Space

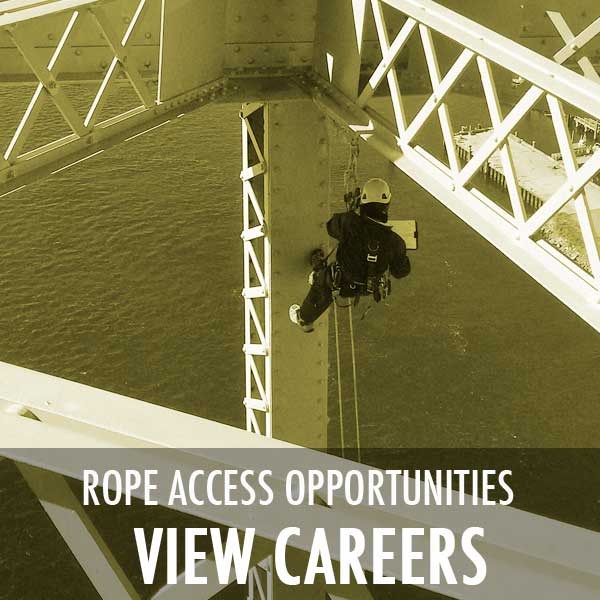

Vertical & High Angle