RAC works on site to fabricate industrial pipe insulation for vessels and pipes. We use a variety of fabrication methods to cut, shape and mold fitting covers and lagging.

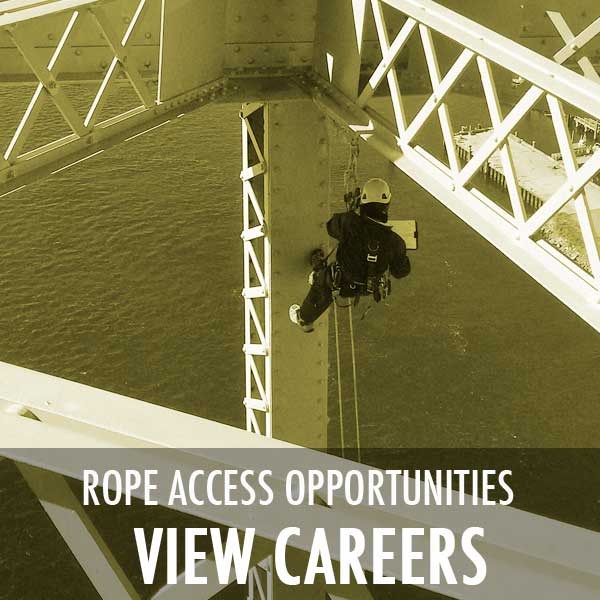

We also install curved sidewall segments for large diameter pipes. Our insulation fabrication team can reach any pipe or mechanical component, no matter how high, confined or congested its location. By utilizing rope access, our swift and maneuverable teams of skilled tradesman ensure that no joint or component goes unprotected. Fabricated pipe insulation controls condensation, mitigates freezing, reduces energy costs and protects workers from extreme temperatures. Not to mention the fact that it preserves product quality by maintaining appropriate temperatures. Thermal insulation can dramatically improve product integrity, operational efficiency and facility sustainability. Our fabrication teams setup containment areas and careful workflows to ensure minimal disruption to your facility and its processes. We custom cut and clad all fabricated insulation to properly protect it from condensation buildup and environmental moisture. Whether you need an elevated system fully insulated or a boiler wrapped, we are here to help you meet your process efficiency, environmental and heat savings needs.