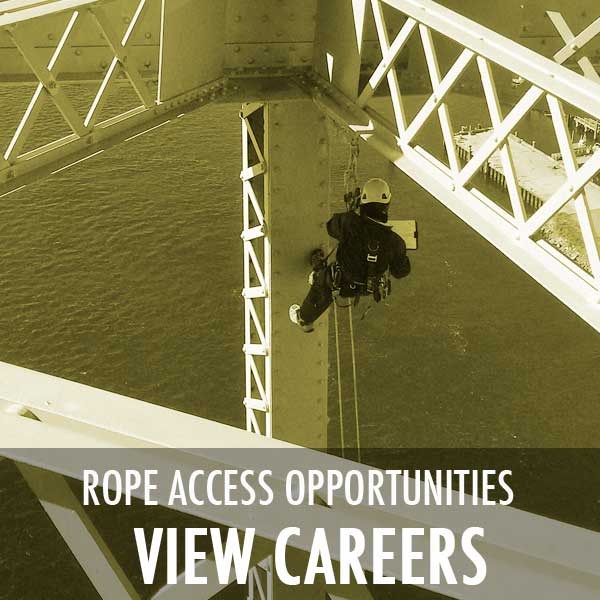

For large metal surfaces and unusually shaped structures, routine testing can present considerable challenges. With rope access Positive Material Identification you can ensure the proper composition of metal alloys in places you never imagined instrumentation could reach.

Positive Material Identification is a stock-in-trade technique for providing quality assurance of your metal materials. It works on metal and high temperature components to answer repair and technical questions. Positive Material Identification, or PMI, is particularly vital to component manufacturing, industrial plants and the petrochemical industry. Significant accidents have occurred in refineries and energy plants when positive material identification was not properly measured. This testing provides rapid verification of alloys used in critical process components, reaction vessel materials, pipes, valves, and welds. It can also accurately determine light, trace and tramp elements for hydrofluoric acid alkylation, FAC modeling and sulfidation systems. When you need proof of traceability on a hard to reach surface or component, rope access Positive Material Identification can get you it. Rope access Positive Material Identification testing uses a handheld x-ray fluorescence analyzer to rapidly reach and evaluate places you could never imagine getting instrumentation. You can rest assured knowing the compositional integrity of your metal alloy components. Testing abilities of Positive Material Identification: Trace elements that can be identified by Positive Material Identification include Magnesium to Sulfur and carbon, boron and phosphorus by special request. PMI ensures the right metallurgy is in the right place in energy plants and industrial processing facilities to keep them safe and reliable. With rope access, we can test any hard-to-reach surface or confined space component for testing. Our industry standard is built around double safety protection measures ensuring low risk and minimal disruption to your operations.