Ultrasonic testing is an essential tool for examining the quality of structural welds, steel beams, forgings, pipelines, tanks, frames, turbines and other heavy machinery. It can also be used on concrete, wood and composite surfaces though with less definitive results.

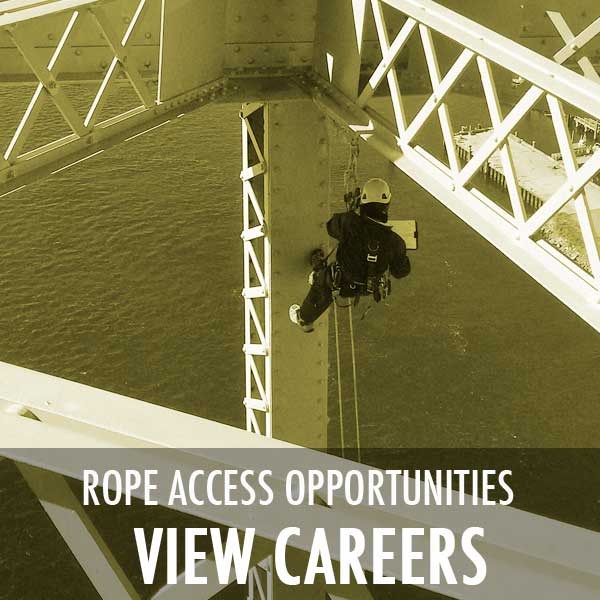

Ultrasonic testing is the most deeply penetrating method of non-destructive examination. It is highly accurate for determining size and shape and provides instantaneous results. Ultrasonic testing is typically used for evaluating: Rope access ultrasonic testing is particularly useful for large and industrial facilities. Some examples of these include construction sites, amusement parks, extraction sites, resource processing facilities, transport or storage vessels and skyscrapers. Our testing can provide volumetric data of materials (whether raw, process components or finished) and detect flaws in a variety of wrought and finished metals and plated items. Ultrasonic testing examines for cracks, lack of fusion, gas holes, laminations, shrinkages and voids. The testing equipment is easy to transport and provides rapid results. With the help of rope access you’ll have your results quickly and cost-effectively. If you have a confined or difficult access structure or vessel that needs evaluation, our Rope Access ultrasonic testing technicians can swiftly reach the seemingly inaccessible. We’ll save you the unnecessary time and costs of scaffolding or platform placement and you’ll receive valuable knowledge of any imperfections or changes in your structure or asset’s material properties. Ultrasonic testing uses high frequency sound waves to measure the thickness and internal structure of dense materials. This type of testing is completely nondestructive and only requires access from one surface. There are no health hazards and results are consistently reliable. Gage readings taken from ultrasonic testing are highly accurate. The test results take the form of detailed visual data on interior thickness and structure. Results available for analysis at time of inspection. This makes ultrasonic testing ideal for evaluating the interior condition of things like pipework corrosion.

Benefits of Ultrasonic Testing